Welcome to WINSUM TEXTILES CO.,LTD

Toggle Navigation

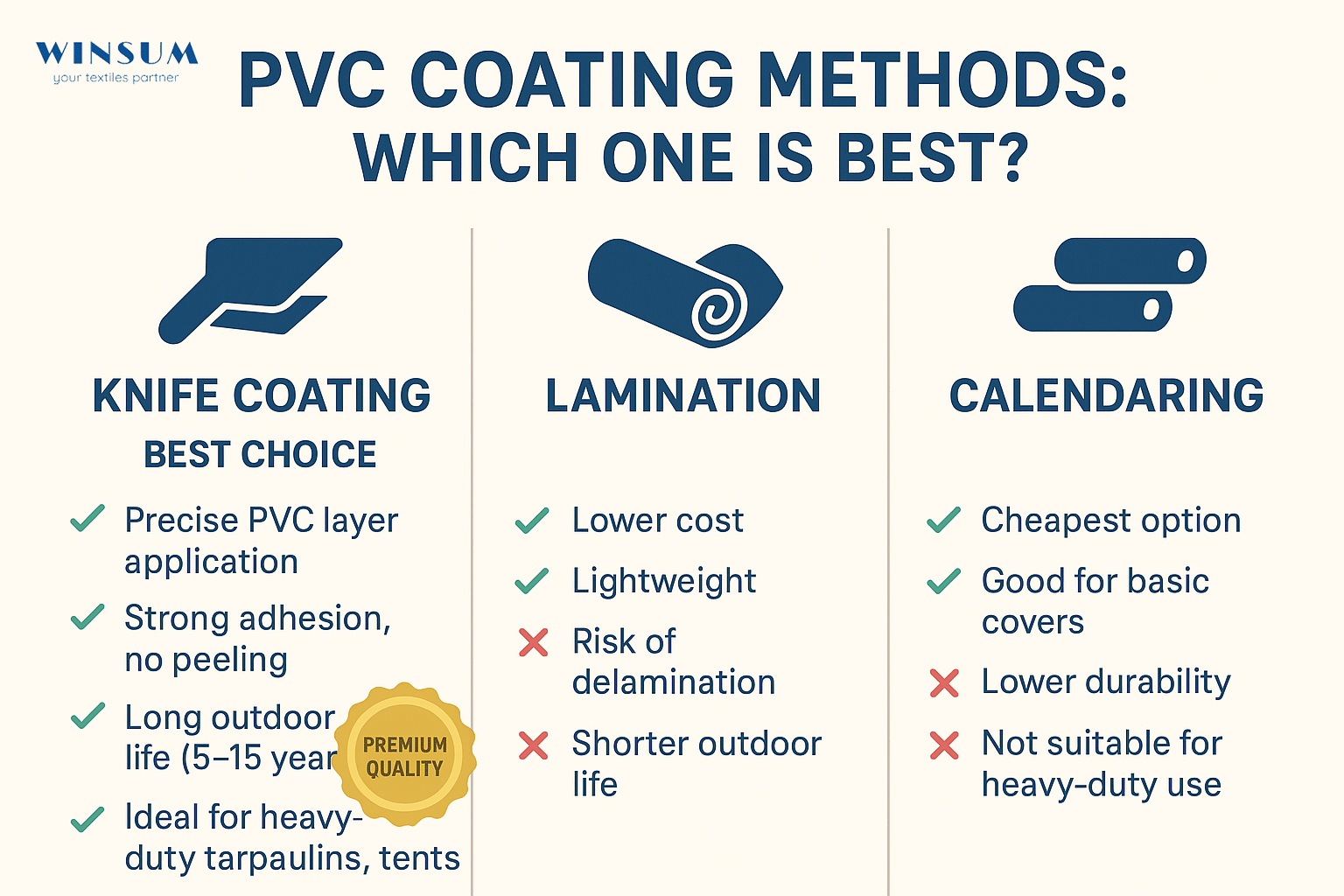

When choosing PVC-coated polyester fabrics, the coating process determines quality, durability, and performance. The three main methods are Knife Coating, Lamination, and Calendaring. Here’s what you need to know.

Knife coating is the premium method for applying PVC to polyester fabric. A liquid PVC paste is spread evenly with a precision knife blade, layer by layer. This creates strong adhesion, a smooth finish, and long-term outdoor durability.

✅ Advantages:

Strongest bond between PVC and fabric

Long lifespan (5–15 years outdoors)

Excellent flexibility and peel resistance

Customizable thickness and surface texture

Best For: Truck covers, tarpaulins, tents, inflatable structures, pool liners, biogas domes.

Lamination bonds a pre-made PVC film to the fabric using adhesive or heat. While cheaper, it can have delamination issues over time and offers lower outdoor durability.

✅ Advantages:

Lower cost than knife coating

Lightweight and easy to handle

Limitations:

Moderate adhesion strength

Shorter outdoor life (3–8 years)

Best For: Light-duty tarps, indoor covers, temporary structures.

Calendaring uses rollers to press PVC onto the fabric. This is the most economical option, but with limited coating penetration and flexibility.

✅ Advantages:

Lowest cost option

Suitable for basic applications

Limitations:

Moderate adhesion

Lower flexibility

Not ideal for heavy-duty or long-term use

If you need maximum durability, weather resistance, and performance, knife coating is the clear winner. It’s the industry standard for heavy-duty tarpaulins, truck covers, inflatables, and industrial structures.

Looking for high-quality knife-coated PVC fabrics? We manufacture premium-grade materials for tarpaulins, tents, pool liners, and custom applications.