Welcome to WINSUM TEXTILES CO.,LTD

Toggle Navigation

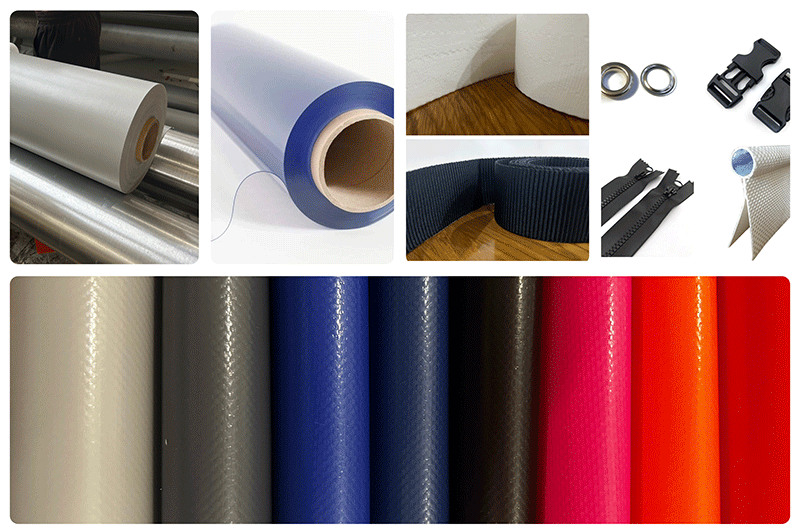

PVC (Polyvinyl Chloride) coating is a process where a fabric is coated with a layer of PVC, a synthetic plastic polymer. This coating is commonly applied to fabrics like polyester or nylon, and it enhances their performance by providing a variety of functional benefits. Here are the main ways PVC coating improves fabric performance:

PVC-coated fabrics are highly resistant to water, making them ideal for outdoor applications like tents, rain gear, tarps, and outdoor furniture. The PVC coating acts as a waterproof barrier, preventing water from soaking through the fabric.

The PVC coating increases the overall durability of the fabric. It helps the fabric resist abrasion, tearing, and UV degradation, making it suitable for use in harsh environments where the fabric is exposed to wear and tear or direct sunlight.

PVC coatings can maintain a good level of flexibility, which helps the fabric retain its pliability even in cold temperatures. This flexibility is important in applications such as outdoor clothing or covers for vehicles, where the fabric needs to bend and stretch without cracking.

PVC-coated fabrics are resistant to many chemicals, oils, and solvents, making them suitable for industrial applications where the fabric might come into contact with hazardous substances.

The smooth, non-porous surface of PVC-coated fabric makes it easy to clean and maintain. It resists stains and dirt, and many products made from this material can be wiped down with a damp cloth.

PVC coating can enhance the appearance of fabrics by giving them a glossy, shiny finish. This makes them more visually appealing in applications like banners, signs, and advertising materials.

Some PVC coatings can also be treated to be flame-resistant, providing added safety for fabrics used in environments where fire risk is a concern, such as tents or industrial coverings.

In short, PVC coating provides a fabric with greater protection, durability, and functionality, making it ideal for both industrial and consumer products.