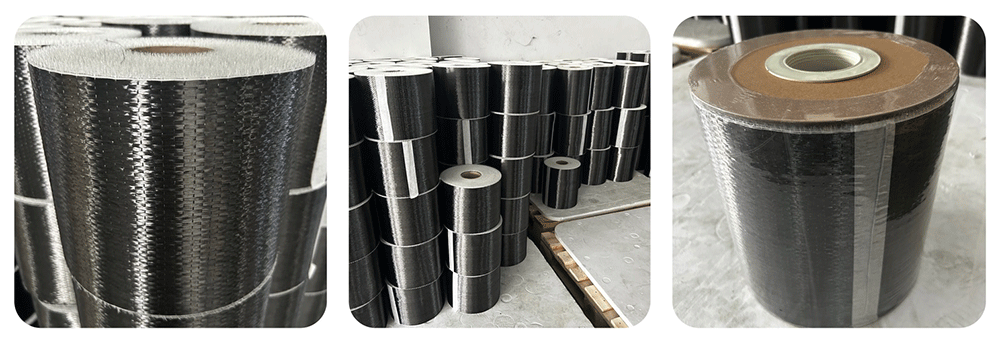

Unidirectional Carbon Fiber

Source:未知Author:admin Addtime:2023-11-09 18:28:07 Click:

12K Unidirectional Carbon Fiber Reinforement Polymer (CFRP)

Product description

Unidirectional carbon fiber fabric is a type of composite material that consists of carbon fibers arranged in a single direction within a matrix material, typically epoxy resin. The carbon fibers in unidirectional fabric are aligned parallel to each other, which gives the material its name, "unidirectional."

Characteristics

Directional Strength: Unidirectional carbon fiber fabric exhibits exceptional strength in the direction of the fibers. This characteristic is particularly advantageous when a component or structure primarily experiences loads along a specific axis.

Product description

Unidirectional carbon fiber fabric is a type of composite material that consists of carbon fibers arranged in a single direction within a matrix material, typically epoxy resin. The carbon fibers in unidirectional fabric are aligned parallel to each other, which gives the material its name, "unidirectional."

Characteristics

Directional Strength: Unidirectional carbon fiber fabric exhibits exceptional strength in the direction of the fibers. This characteristic is particularly advantageous when a component or structure primarily experiences loads along a specific axis.

Lightweight: Carbon fibers are renowned for their low density, contributing to the lightweight nature of unidirectional fabric. This attribute is crucial in applications where weight reduction is critical.

High Stiffness: Carbon fibers have a high modulus of elasticity, resulting in a stiff material. This stiffness minimizes deflection under load, which is important in applications where structural rigidity is paramount.

Tailorability: Unidirectional carbon fiber fabric can be customized to meet specific requirements. Engineers can adjust the fiber orientation, the type of matrix material (commonly epoxy resin), and the number of plies to tailor the mechanical properties for different applications.

Corrosion Resistance: Carbon fibers are inherently corrosion-resistant, making unidirectional fabric suitable for use in harsh environments, where protection against environmental factors is essential.

Fatigue Resistance: These materials are highly resistant to fatigue, ensuring a long service life even under cyclic loading conditions.

Thermal Conductivity: Carbon fibers have relatively low thermal conductivity, which can be advantageous in applications where thermal insulation or minimal heat transfer is required.

Balanced Anisotropy: Unidirectional fabric offers anisotropic properties, meaning its mechanical characteristics vary with orientation. Engineers can harness this anisotropy by combining multiple layers or orientations of fabric to achieve balanced mechanical properties in different directions.

High Cost: Unidirectional carbon fiber fabric can be expensive due to the cost of carbon fibers and the manufacturing process. However, the high performance and durability of the material can often justify the cost in applications where its unique properties are essential.

Applications

-

Structural Strengthening: Unidirectional carbon fiber composites can be used to reinforce and strengthen existing building structures, such as bridges, beams, columns, and slabs. This technique can help extend the service life of older buildings or structures that require additional load-bearing capacity.

-

Seismic Retrofitting: In regions prone to seismic activity, unidirectional carbon fiber composites can be applied to enhance the seismic resistance of buildings by improving their structural integrity. This retrofitting helps reduce the risk of damage during earthquakes.

-

Column and Beam Wrapping: Carbon fiber wrapping can be applied to columns and beams to increase their load-carrying capacity, enhance durability, and mitigate corrosion.

-

Masonry Retrofitting: In the case of historic buildings with masonry walls, unidirectional carbon fiber composites can be used to reinforce and stabilize these structures while preserving their architectural integrity.

-

Concrete Repair: Carbon fiber-reinforced polymers can be employed in concrete repair and rehabilitation to mend and enhance the performance of deteriorating or damaged building elements, such as beams and slabs.

-

Tendon Protection: CFRP can be used to protect and enhance the durability of post-tensioned tendons used in building construction. The application of CFRP prevents corrosion and extends the life of the tendons.

-

Sustainability: The lightweight nature of carbon fiber composites can be beneficial in reducing the overall weight of a building's structural elements, which may lead to cost savings and reduced environmental impact.

-

Residential Construction: In residential construction, CFRP can be used to strengthen foundations, walls, and other structural components, as well as to retrofit existing structures for increased load-bearing capacity.

-

Bridge Deck Strengthening: In building bridges and walkways, CFRP composites can be used to strengthen and extend the life of the bridge deck, improving its durability and resistance to heavy traffic loads.

-

Custom Architectural Elements: Architects and designers can use CFRP composites to create custom, lightweight, and aesthetically pleasing architectural elements in building design.

-

Facade and Cladding Systems: Unidirectional carbon fiber composites can be used as part of facade systems to enhance the aesthetics and performance of building exteriors.

Technical Data

12K Dry Fiber

|

Tensile Strength (MPa) |

5100 |

|

Tensile Modulus (GPa) |

233 |

|

Elongation (%) |

2.2 |

12K Unidirectional Carbon Fiber High Strength Grade I

|

Model |

Weight (g/m2) |

Tensile Strength (MPa) |

Tensile Modulus (GPa) |

Elongation (%) |

Thickness (mm) |

|

WT-20 |

200 |

3800 |

265 |

1.70 |

0.111 |

|

WT-30 |

300 |

4300 |

265 |

1.95 |

0.167 |

Color Black

Width 10mm/20mm/30mm/40mm/50mm/100mm

Length 100m

Service Life 10-20 years after put into use

Package Cartons

Production Capacity 300000 square meters per month